The unsightly pink hues of various garments on my washing line are an aberration. And, in my opinion, an abomination.

Every time I glance out the window and catch the sight of the pinky glow I feel a little schizophrenic. There's is no way those clothes could belong to anyone in my house. Alas, the stinky pink is evidence of my not quite successful fabric dyeing attempts.

Quite a while ago I was given a large bag of baby/toddler clothing hand me downs, much of which was pink. Some of the offending items were of good quality and nicely made/styled, so I decided to keep them for dyeing later on.

I finally got around to dyeing the pink pile with red Teri dye (I was given than also), and the result wasn't red but fuchsia. There wasn't anything wrong with the dye, but it wasn't the right chemicals for the cellulose blends. I foolishly failed to notice that the jars said very clearly "for wool and silk". My next attempt was a grey and pink woollen poncho and a navy jersey, both of which absorbed the dye well. They will both need to go through another dyeing cycle because the dye solution was partly exhausted by the unfortunate cotton intrusion.

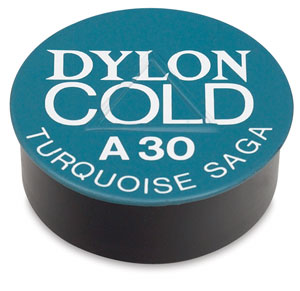

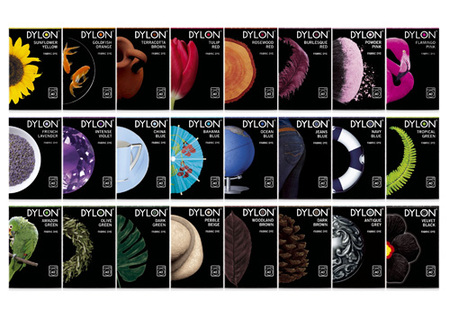

I now need to get my hands on some dye that works well on cotton, like Procion. Something that is not Dylon. Damn you, diabolical Dylon. I've used their fabric dyes in the past, years ago, and on numerous occasions. They were sold in tiny tins that dyed 250g of fabric for $3. Now they've "rebranded", changed their packaging to sachets, and the same amount of dye costs $7. What a rip off! They downsized their wide range of reds in preference of the unpleasantly pinkish Tulip Red. They have clearly opted for style over substance.

Every time I glance out the window and catch the sight of the pinky glow I feel a little schizophrenic. There's is no way those clothes could belong to anyone in my house. Alas, the stinky pink is evidence of my not quite successful fabric dyeing attempts.

Quite a while ago I was given a large bag of baby/toddler clothing hand me downs, much of which was pink. Some of the offending items were of good quality and nicely made/styled, so I decided to keep them for dyeing later on.

I finally got around to dyeing the pink pile with red Teri dye (I was given than also), and the result wasn't red but fuchsia. There wasn't anything wrong with the dye, but it wasn't the right chemicals for the cellulose blends. I foolishly failed to notice that the jars said very clearly "for wool and silk". My next attempt was a grey and pink woollen poncho and a navy jersey, both of which absorbed the dye well. They will both need to go through another dyeing cycle because the dye solution was partly exhausted by the unfortunate cotton intrusion.

I now need to get my hands on some dye that works well on cotton, like Procion. Something that is not Dylon. Damn you, diabolical Dylon. I've used their fabric dyes in the past, years ago, and on numerous occasions. They were sold in tiny tins that dyed 250g of fabric for $3. Now they've "rebranded", changed their packaging to sachets, and the same amount of dye costs $7. What a rip off! They downsized their wide range of reds in preference of the unpleasantly pinkish Tulip Red. They have clearly opted for style over substance.

|

| The old Dylon packaging |

|

| The new Dylon |